Zenesys handles every phase of large-scale infrastructure execution, blending expert engineering, strategic procurement, and precise construction management. Our “one-stop” EPC model assures coordination across all disciplines—civil, mechanical, electrical, instrumentation—while minimizing project risks and optimizing cost-efficiency.

Engineering Mastery

-

Multi-disciplinary synergy (process design, mechanical layouts, electrical systems, etc.).

-

AI-driven modeling to optimize plant layouts and resource flows.

-

Environmental & Social Impact: Performing ESG-centric reviews, community engagement, and risk mitigation to ensure projects balance economic gains with societal uplift.

Procurement Strength

-

Global vendor networks (Japan, USA, Europe) for top-tier equipment and materials.

-

Transparent bidding and QA processes, ensuring cost-control and timely deliveries.

-

Digital tracking of materials in real-time, reducing delays and inventory overhead.

Construction Precision

-

On-site PMOs that unify teams under a singular project vision.

-

In-depth HSE (Health, Safety, Environment) protocols, ensuring worker well-being and environmental safeguards.

-

Agile methodologies for swift adaptation to site conditions or design changes.

Zenesys FEED and detailed engineering services lay the groundwork for seamless project execution. Our specialists translate feasibility studies into actionable blueprints, applying data analytics, digital twin simulations, and ESG evaluations to refine plant layouts, pipeline routes, or power generation schematics. This meticulous planning reduces rework, contains costs, and ensures every project milestone hits its mark.

FEED & Feasibility

-

Site analysis (geotechnical surveys, resource availability, environmental data).

-

Demand forecasting and cost modeling.

-

Risk profiling and contingency planning.

Digital Twin & Simulation

-

3D models continuously updated with real-time project data.

-

Stress testing for mechanical integrity, flow rates, or seismic resilience.

-

Predictive analytics for lifecycle cost optimization.

Detailed Engineering

-

Generation of final design documents, BOM (Bill of Materials), P&IDs.

-

Scheduling and resource allocation set with micro-level precision.

-

Robust change management and version control to maintain design integrity.

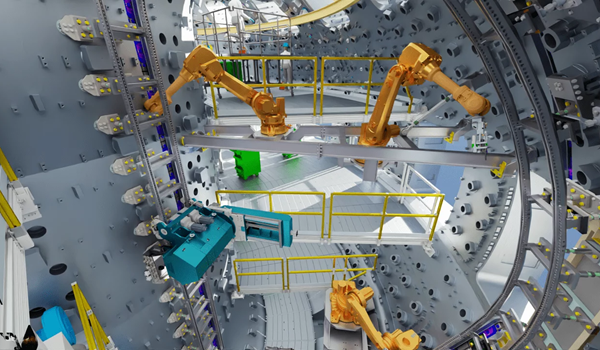

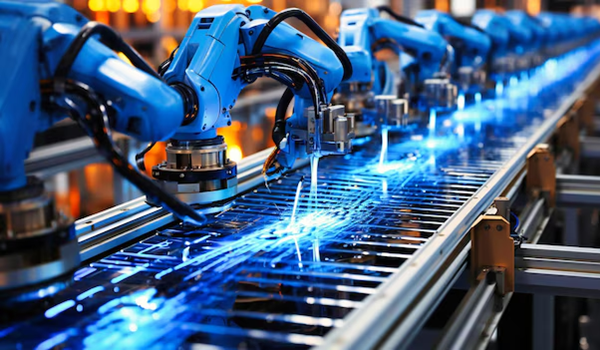

Zenesys leverages the newest breakthroughs—modular construction, robotic fabrication, drone- based inspections—to consistently deliver on accelerated timelines while upholding top-tier safety and environmental standards. Our synergy of field-proven tactics and cutting-edge technology ensures every site is a testament to modern engineering excellence.

Modular Construction & Pre-Fabrication

-

Off-site assembly of standardized modules, then transported for final installation.

-

Reduced site congestion, improved quality control in controlled factory settings.

-

Shorter project schedules and minimized environmental footprint.

Digital Twin & Real-Time Monitoring

-

4D modeling integrates scheduling data for construction staging.

-

IoT sensors for real-time structural integrity checks, equipment usage, and worker safety compliance.

-

AI-driven analytics identify bottlenecks or potential schedule slips early.

High-Tech Fabrication & Automation

-

Robotic welders, CNC machines, and advanced scanning for precise tolerances.

-

Use of specialized alloys or composites to extend asset lifespans.

-

Strategic shipping logistics for large modules across borders.

Through strategic partnerships with engineering leaders (e.g., Fluor, JGC, TechnipFMC) and strict adherence to ISO, ASME, and API guidelines, Zenesys ensures every project meets the highest benchmarks for quality, safety, and ethical conduct. Our local ecosystem alliances—certified subcontractors, experienced consultants, and community liaisons—further enrich project deliverables with regional insights and lasting social value.

Strategic Engineering Alliances

-

Access to specialized design tools, proprietary technologies, and global expertise.

-

Co-development of complex refineries, LNG terminals, and multi-country pipeline systems.

ESG & HSE Excellence

-

Zero-harm philosophy integrated into site operations.

-

Environmental frameworks that reduce emissions, preserve biodiversity, and respect local livelihoods.

-

Transparent reporting aligned with GRI or SASB standards.

Local Engagement & Capacity Building

-

Training local engineers, technicians, and site managers to encourage skill transfer and local empowerment.

-

Respectful community dialogue, ensuring transparent land acquisition and inclusive stakeholder consultations.